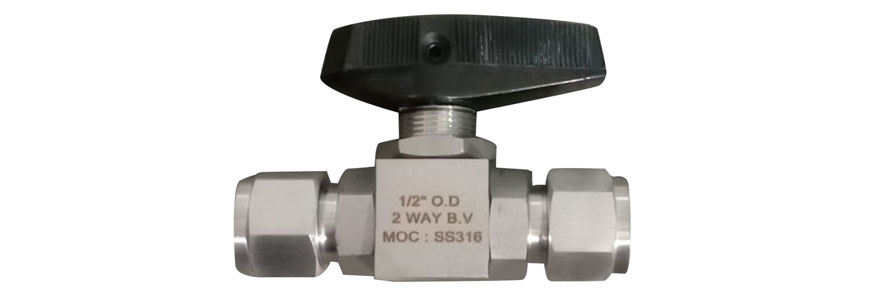

In the intricate landscape of industrial fluid control, the Stainless Steel 2 Way Ball Valve emerges as a pivotal component, combining precision, durability, and versatility. Crafted to meet the demanding requirements of a wide array of environments, this valve stands as a testament to engineering excellence. Whether it’s managing water flow, regulating chemical substances, or controlling gas paths, the stainless steel 2 way ball valve ensures seamless operation and reliability. Let’s delve into the specifics of this indispensable tool, highlighting its construction, benefits, and the integral role it plays in various sectors.

The Essence of Stainless Steel 2 Way Ball Valves

A stainless steel 2 way ball valve is characterized by its simple yet effective design: a ball with a bore (hole) at its center, encased in a body of durable stainless steel. The valve’s operation is straightforward—rotating the ball by 90 degrees opens or closes the flow path. This design not only facilitates easy operation but also ensures a tight seal, significantly reducing the risk of leaks. The choice of stainless steel as the material further enhances the valve’s longevity and resistance to corrosion, making it suitable for use with a wide range of fluids, including aggressive chemicals and high-temperature substances.

Advantages of Stainless Steel 2 Way Ball Valves

Reliability and Durability

Stainless steel’s inherent resistance to corrosion, rust, and staining, coupled with its strength, makes these ball valves exceptionally durable and reliable. They are designed to withstand harsh conditions and aggressive fluids without degradation, ensuring long-term performance and minimal maintenance.

Precision Flow Control

The precise control afforded by the 2 way ball valve design allows for accurate regulation of fluid flow. This is crucial in applications where maintaining specific flow rates or pressures is essential for safety and efficiency.

Versatility Across Applications

From the petrochemical industry to water treatment plants, and from pharmaceutical manufacturing to food and beverage processing, the versatility of stainless steel 2 way ball valves makes them a staple in countless applications. Their suitability for a range of temperatures and pressures further broadens their applicability across sectors.

The Role in Industry

Chemical Processing

In chemical processing, where the handling of corrosive or hazardous substances is commonplace, the chemical resistance of stainless steel 2 way ball valves ensures safe and effective fluid management.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems benefit from the precise control and durability of these valves, regulating temperatures and flow rates efficiently within residential, commercial, and industrial settings.

Water and Wastewater Management

The robustness of stainless steel 2 way ball valves against corrosion makes them ideal for water and wastewater management applications, ensuring reliable operation in environments where moisture and contaminants are prevalent.

Conclusion: A Foundation of Flow Control Excellence

The stainless steel 2 way ball valve by Pioneer Industries represents a cornerstone of flow control solutions across industries. Its combination of precision, durability, and versatility makes it an invaluable asset in the quest for efficient and reliable fluid management. As technology advances and the demands of industrial applications evolve, the stainless steel 2 way ball valve continues to stand as a symbol of quality and reliability, playing a critical role in shaping the future of industry.

Contact Us Today to explore how our Stainless Steel 2 Way Ball Valve can elevate the performance and efficiency of your industrial processes.