In industries dealing with chemicals, saltwater, acids, or reactive gases, even a small leak or material failure can lead to operational downtime or safety hazards. That’s why stainless steel female connectors have become the gold standard for piping and instrumentation systems in corrosive environments. They provide unmatched chemical resistance, secure sealing, and long-term durability — making them ideal for harsh operating conditions.

🔧 Browse Stainless Steel Fittings →

What is a Stainless Steel Female Connector?

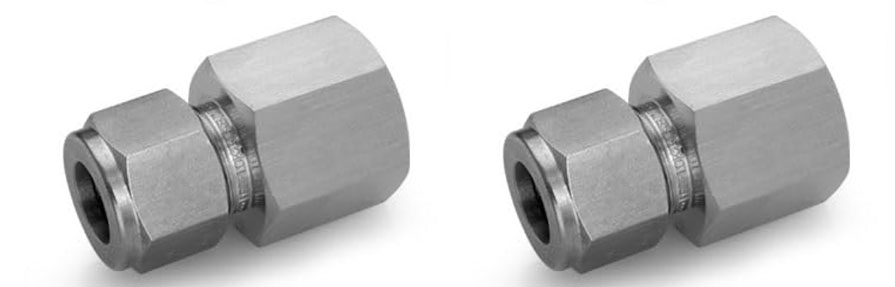

A stainless steel female connector is a compression-style tube fitting with a female-threaded end (typically NPT or BSPT) that connects to a male-threaded component. The other end features a double ferrule tube grip, creating a leak-tight seal in high-pressure fluid or gas systems. These connectors are widely used for tube-to-thread transitions in corrosive and high-purity applications.

Why Female Connectors are Critical in Corrosive Applications

In corrosive systems, reliability and material compatibility are non-negotiable. Stainless steel female connectors play a critical role in ensuring:

- Leak-free performance under pressure

- Resistance to pitting, crevice, and galvanic corrosion

- Compatibility with hazardous chemicals, brines, acids, and solvents

- Safe transitions between tubing and threaded instrumentation

- Long service life, even in continuous exposure to harsh media

Industries such as chemical processing, marine, pharma, and wastewater treatment rely on these fittings to maintain system integrity in demanding conditions.

🔍 See Our Full Product Range →

Trends, Challenges & Common Questions in Corrosive Environments

🔍 Trends:

- Increased demand for SS316L over SS304 in aggressive media

- Use of female connectors in modular skids and compact panels

- Standardization of double ferrule designs for leak prevention

⚠️ Challenges:

- Premature corrosion from substandard alloys

- Thread galling or misalignment with incompatible materials

- Failures due to thermal expansion, vibration, or seal fatigue

❓ Common Buyer Queries:

- What grade of stainless steel is best for acidic applications?

- Can female connectors handle both fluid and gas lines?

- Are SS female connectors suitable for outdoor/marine use?

📞 Speak to a Technical Expert →

How Pioneer’s Stainless Steel Female Connectors Withstand Corrosive Environments

At Pioneer Fitting, our stainless steel female connectors are specifically engineered for applications that involve corrosive chemicals, marine exposure, high humidity, and aggressive process media.

Each fitting is:

- Manufactured using SS316 or SS316L, known for excellent corrosion resistance

- CNC-machined for thread accuracy and minimal galling risk

- Compatible with double ferrule systems to ensure leak-tight sealing

- Pressure-tested to guarantee performance up to 6000 PSI

These connectors are ideal for harsh environments where system failure is not an option.

🧪 Explore Stainless Steel Fittings Built for Corrosion Resistance →

Industry Use Cases for Female Connectors in Harsh Conditions

| Industry | Corrosive Exposure | Connector Use Case |

|---|---|---|

| Chemical Processing | Acids, solvents | Instrument loop connections, chemical dosing skids |

| Marine / Offshore | Saltwater, humidity | Tubing-to-valve connections in engine rooms and decks |

| Pharma & Biotech | Cleaning agents, sanitizers | CIP systems and sensor mounting |

| Water Treatment | Chlorinated water, wastewater gases | Inline pressure sensor setups |

| Oil & Gas | Sour gas, brine, H₂S | Flow panel instrumentation, sampling ports |

These connectors serve as stable, corrosion-resistant transition points between tubing and threaded components — valves, gauges, manifolds, and more.

Technical Features of Pioneer Female Connectors

- Material: SS316 / SS316L

- Tube OD Range: 1/8″ to 1″ (Imperial & Metric)

- Thread Options: NPT & BSPT (as per region)

- Working Pressure: Up to 6000 PSI

- Temperature Rating: Suitable for cryogenic to high-temp service

- Surface Finish: Passivated, burr-free, with mirror-smooth bore

- Design Compatibility: Double ferrule systems (front + back ferrule)

All Pioneer connectors undergo 100% pressure testing and are available with MTC and batch traceability.

SS Female Connector vs Brass or SS304 – Corrosion Comparison

| Feature | SS316 Female Connector | Brass Connector | SS304 Connector |

|---|---|---|---|

| Corrosion Resistance | ✅ Excellent | ⚠️ Poor in acids/salts | ⚠️ Moderate in aggressive media |

| Suitable for Marine/Offshore | ✅ Yes | ❌ No | ⚠️ Limited |

| Thread Integrity Over Time | ✅ High | ⚠️ Soft threads | ⚠️ Can seize |

| Temperature Tolerance | ✅ High (up to 800°C) | ⚠️ Limited | ⚠️ Moderate |

| Price vs Performance | ✅ Best value for harsh environments | ✅ Cheap but risky | ⚠️ Mid-range, not always suitable |

💡 Conclusion: For corrosive conditions, SS316 female connectors deliver long-term performance without material failure.

Why Choose Pioneer Fitting for Corrosion-Resistant Female Connectors

Pioneer Fitting combines engineering-grade materials with export-level service to become the preferred choice for stainless steel compression fittings.

Here’s why buyers across industries trust us:

- ✅ SS316/316L only — no compromise on grade or finish

- ✅ Thread accuracy and anti-galling treatment

- ✅ Double ferrule compatible for leak-proof connections

- ✅ Custom sizes, urgent dispatch, and low MOQs

- 🌍 Export-ready packaging and international compliance

- 📈 Trusted by EPCs, OEMs, and distributors worldwide

📞 Talk to Our Team or Request a Quote →

Export, Packaging & Global Delivery Capabilities

Pioneer Fitting supplies stainless steel female connectors across India, the GCC, Southeast Asia, Africa, and Europe, serving B2B buyers in industries where corrosion resistance is critical.

🌍 What We Offer:

- 📦 Export-grade packaging: vacuum-sealed, bubble-wrapped, crated as needed

- ✅ Quick shipping from stocked inventory or made-to-order

- 🧾 Complete documentation: MTC, pressure test reports, COO, packing list, HSN

- 🌐 Global compliance: ASTM, NACE, DIN, ISO-compatible threads and materials

- 🛠️ Support for bulk supply, OEM contracts, and retrofit projects

How to Choose Female Connectors for Corrosive Environments

If your application involves acidic, marine, or chemical exposure, consider the following:

✅ Material:

- Always go for SS316L over SS304 for chemical or saltwater conditions

✅ Thread Type:

- NPT for North America, BSPT for GCC, Asia, and Europe

- Match precisely to avoid galling or leakage

✅ Ferrule System Compatibility:

- Ensure it matches your tube OD and supports double ferrule gripping

✅ Operating Conditions:

- Choose tested fittings with pressure ratings above your operating range

✅ Traceability:

- Request MTC and batch codes to verify metallurgy and standards

Need help choosing the right variant for your system?

📞 Talk to Our Fitting Experts →

FAQs

What is a stainless steel female connector used for?

It’s used to connect tubing to male-threaded components like valves, gauges, or manifolds — especially in high-pressure systems.

Why is SS316 preferred over SS304 in corrosive environments?

SS316 contains molybdenum, which offers superior resistance to chloride, acid, and salt-based corrosion — making it ideal for marine and chemical use.

Can I use female connectors in gas applications?

Yes, Pioneer’s female connectors are pressure-tested and suitable for gas, fluid, and steam lines.

Are these fittings double ferrule compatible?

Absolutely. Our female connectors are designed for use with double ferrule systems for vibration-proof, leak-tight performance.

Do you provide BSPT and NPT thread options?

Yes, both are available based on your regional piping standards.

What pressure can Pioneer’s female connectors handle?

Up to 6000 PSI, depending on the size and tube OD.

Can these fittings be shipped internationally?

Yes, we provide export-ready packaging and documentation for international buyers.

Get a Quote or Ask a Technical Question

Looking for stainless steel female connectors that can withstand corrosion and perform under pressure?

🎯 Pioneer Fitting offers:

- ✅ SS316 / SS316L female connectors

- ✅ BSPT/NPT compatibility

- ✅ Double ferrule grip performance

- ✅ Global delivery + compliance support

🛒 Get a Custom Quote

🔍 Explore Stainless Steel Fittings

🧰 View Full Product Range

Reliability Where It Matters Most

In corrosive environments, even a minor fitting failure can trigger a major shutdown. That’s why Pioneer’s stainless steel female connectors are trusted by engineers across industries. With SS316/316L construction, precision threads, and pressure-tested quality — they’re made for real-world performance.

💡 From marine decks to acid tanks, trust Pioneer Fitting for connections that last.