Pneumatic valves play a pivotal role in the intricate machinery that powers industrial processes, providing a controlled and efficient means of managing air flow. These valves, driven by compressed air, serve as the gatekeepers of pneumatic systems, regulating the passage of air to control various operations within manufacturing and automation settings.

At their core, pneumatic valves are devices designed to control the flow of compressed air in a system. They act as switches that can start, stop, or redirect the airflow, allowing for precise control over the movement of pneumatic actuators and other components. These valves come in a variety of types, each tailored to specific applications and operational requirements.

In the dynamic landscape of industrial operations, precision and reliability are paramount. Pneumatic valves offer a responsive and efficient method for controlling the flow of air, enabling seamless automation and accurate regulation of machinery. From manufacturing lines to complex automated systems, the use of pneumatic valves enhances the overall efficiency of industrial processes, contributing to increased productivity and reduced downtime.

Types of Pneumatic Valves

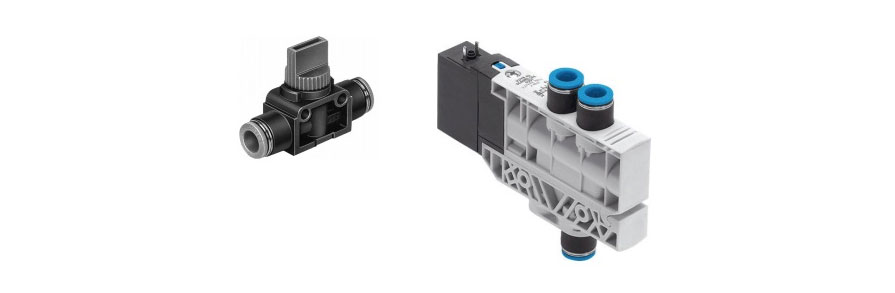

Solenoid Valves: In the realm of pneumatic valves, solenoid valves stand out as fundamental components that play a crucial role in controlling the flow of compressed air within industrial systems. These valves utilize electromagnetic principles to actuate and regulate the passage of air, offering precision and responsiveness in various applications.

Understanding Solenoid Valves:

- Principle of Operation: Solenoid valves operate on the principle of electromagnetism. When an electrical current is applied to the solenoid coil, it generates a magnetic field that moves a plunger or a similar mechanism, thereby opening or closing the valve.

- On/Off Functionality: One of the key features of solenoid valves is their binary nature – they are either fully open or fully closed. This makes them ideal for applications where quick and decisive control over the airflow is necessary.

Applications in Industrial Settings: Solenoid valves find widespread use in various industries, including manufacturing, oil and gas, water treatment, and more. They are employed in tasks such as controlling the flow of air to pneumatic actuators, shutting off gas or liquid flow in emergencies, and automating processes with precise timing requirements.

Top Benefits of Pneumatic Valves in Industrial Processes

Pneumatic valves serve as indispensable components within industrial processes, offering a myriad of advantages that contribute to enhanced efficiency, precision, and overall operational excellence. Here are the top benefits of incorporating pneumatic valves into industrial setups:

- Efficient Automation: Pneumatic valves play a pivotal role in automating various industrial processes. Their rapid response and precise control over airflow enable seamless integration with automated systems, resulting in increased production efficiency and reduced manual intervention.

- Cost-Effective Operation: One of the key advantages of pneumatic valves lies in their cost-effectiveness. The use of compressed air as a power source is often more economical compared to alternative energy sources. Additionally, pneumatic systems tend to have lower maintenance costs, contributing to overall operational savings.

- Reliable and Robust: Pneumatic valves are known for their durability and resilience in demanding industrial environments. Their robust construction ensures reliable performance even in harsh conditions, making them suitable for a wide range of applications across different industries.

- Precise Control and Positioning: The binary nature of many pneumatic valves allows for precise control over the flow of air. This level of accuracy is crucial in applications where specific timing and positioning are essential, such as in assembly lines and robotic systems.

- Quick Response Time: Pneumatic systems, including valves, are characterized by their rapid response time. This quick reaction to input signals ensures swift adjustments in airflow, contributing to the overall agility and responsiveness of industrial processes.

- Safety in Hazardous Environments: Pneumatic systems are inherently safer in certain environments, particularly those with the potential for flammable gases or liquids. The absence of electrical components in direct contact with the medium reduces the risk of sparks, making pneumatic valves a preferred choice in hazardous locations.

- Ease of Maintenance: Pneumatic valves are designed for ease of maintenance. Regular inspections, lubrication, and simple repairs contribute to extended valve lifespan and minimized downtime, ensuring continuous and reliable operation.

Understanding and leveraging these benefits are crucial for industries aiming to optimize their processes and achieve greater efficiency. In the subsequent sections, we will delve into specific applications and case studies where the advantages of pneumatic valves shine through.

Where to Buy High-Quality Pneumatic Valves

When it comes to sourcing high-quality pneumatic valves, Pioneer Industries stands out as a premier choice in the market. As one of India’s leading manufacturers and exporters of pneumatic valves, we have established ourselves as a reliable and reputable supplier with a global reach. With a strong commitment to quality, the company has been catering to the needs of clients in over 85 countries, exporting and manufacturing on a large scale.

Pioneer Industries takes pride in its comprehensive range of pneumatic valves designed to meet the diverse requirements of industries worldwide. Our products undergo rigorous quality control processes to ensure precision, durability, and adherence to international standards. In addition to product quality, we emphasize efficient logistics and customer support, ensuring a seamless experience for clients across the globe. As the industrial landscape continues to evolve, Pioneer Industries remains at the forefront, providing innovative and reliable pneumatic valve solutions that contribute to the success and efficiency of industrial processes.

For those seeking a trusted partner in the procurement of pneumatic valves, Pioneer Industries emerges as a name synonymous with quality, reliability, and a commitment to meeting the evolving needs of the global market. Contact Us Today!